For the new beachfront development Sabah Al-Ahmed Sea City, 85km south of Kuwait City, equipment specialist RMD Kwikform has provided a wide range of formwork and shoring to developer La?ala Al-Kuwait Real Estate Co., to help construct two of the main bridge structures

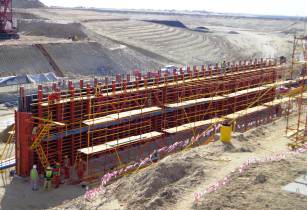

Known as the west and east bridges, the 42.5m wide x 94m long structures are part of phase A4 of the Sea City development, providing links over the canals across the islands.

Requiring a complete formwork and shoring solution for the construction of the bridges, including foundations, piers, soffits, abutments and safety barriers, engineers from RMD Kwikform worked with the project design team to create a package of equipment, combining specialist formwork with standard components.

With the design of the two large piers spanning the width of the bridge deck, including decorative windows and bull nosed ends, RMD Kwikform engineers developed special steel end forms and arched window sections to achieve the required concrete finish.

In addition to these specially designed solutions, 22 sets of reusable curved steel barrier forms were designed and fabricated in the UAE to support the construction of concrete safety barriers for both sides of each bridge.

For the main abutments, a combination of steel Superslim Soldiers and timber GTX beams were used to create a variety of wall formwork solutions, reaching up to heights of 17.12m. For the main end wall sections, due to the size and location of the abutments, multiple Superslim soldier bracing members had to be used at varying angles to ensure the wall forms remained in place, when concrete was poured.

For the construction of the bridge soffits, the erection team opted to use the specialist Paraslim composite bridge system from RMD Kwikform, taking full advantage of using the C-Hook crane attachment to lift Paraslim sections assembled on the ground into place. Once the sections were cast, the C- Hook was then also used to remove moving them onto the next pour, reducing the need to work at height and speeding up the overall process.

Andrew Gardner of RMD Kwikform said, ?This project involved a great deal of co-ordination with the client and design team as all of the solutions had to be signed off before the specially designed equipment could be fabricated and the required standard equipment shipped from the UAE to Kuwait.

?This is why the site team looked to take full advantage of an integrated approach, sourcing all of the equipment from RMD Kwikform. In-turn this allowed the erection team to benefit from onsite training through our site assistance team, speeding up the cycle times.?