Hydrogen and helium may be made up of small molecules but have a big role to play in the technology innovations of the future

From the natural gas that underpins power generation to the carbon dioxide emissions driving the climate crisis, there is no denying gases have a significant impact on modern life, according to Eve Pope, senior technology analyst at IDTechEx.

The two lightest gases - hydrogen and helium - may be made up of small molecules but have a big role to play in the technology innovations of the future. Key application areas include mobility, power generation, and semiconductor manufacturing.

Hydrogen power

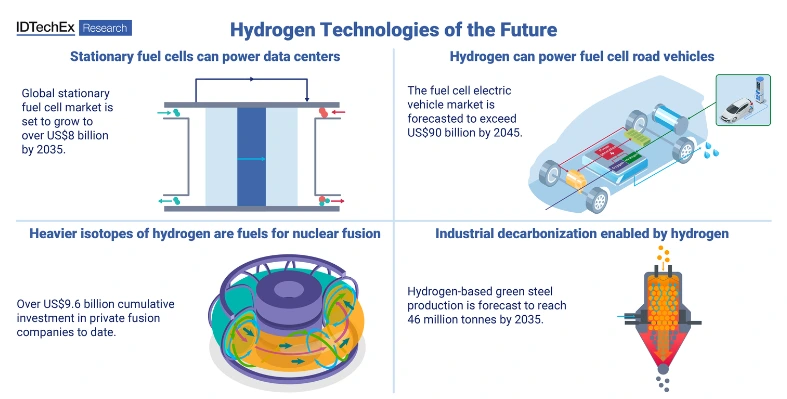

Hydrogen is an energy carrier that could replace fossil fuels to power the future. Fuel cells can convert hydrogen gas into electricity through a chemical reaction with oxygen. Because solid oxide fuel cells have a long operating lifetime and fuel flexibility, they are well-suited to the continuous power generation required for sustainable data centres. As the AI boom continues, some data centres are already using solid oxide fuel cells running on natural gas, with plans to transition over to low-carbon hydrogen once economics and infrastructure can make this commercially feasible.

For cars, fuel cell electric vehicles can also be powered by the reactions between stored hydrogen and oxygen in the air. Markets for fuel cell electric vehicles will depend upon national investments in green hydrogen projects and rollouts of hydrogen refueling stations.

Industrial decarbonisation of iron and steel enabled by hydrogen

For iron and steel, natural gas direct reduced iron (DRI) production using shaft furnaces is already mature. Hydrogen-based DRI (H2-DRI) processes represent the next logical evolution toward greener steel production. Midrex and Energiron shaft furnace plants have successfully demonstrated the use of hydrogen or hydrogen-rich gases, as evidenced in projects like HYBRIT by SSAB in Sweden and HBIS Group in China.

The success of hydrogen-based green steel production will depend heavily upon the availability of green and blue hydrogen and supporting infrastructure, with IDTechEx’s “Green Steel 2025-2035: Technologies, Players, Markets, Forecasts” report forecasting that 46 million tonnes of steel will be produced enabled by hydrogen in 2035.

Hydrogen isotopes for nuclear fusion

Even the heavier isotopes of hydrogen have a role to play. Deuterium and tritium are essential fuels for nuclear fusion technologies, hoped to provide energy-dense, continuous sources of green energy with no risk of meltdown. According to IDTechEx’s “Fusion Energy Market 2025-2045: Technologies, Players, Timelines” report, commercial fusion companies have raised over US$9bn to date, while an increasing number of governments see fusion as the modern day 'space race'. Players are pursuing different reactor designs and fuels, leading to various materials opportunities and supply chain challenges.

Helium required for semiconductor manufacturing

Helium is widely used in manufacturing processes due to its cooling and inert properties. It is crucial for thermal management during semiconductor production. As semiconductor manufacturing advances towards smaller nodes (essential for AI, autonomous vehicles, etc.), reliance on helium will continue to grow. Helium is a finite resource, so technologies for helium production and helium substitutes covered in IDTechEx’s “Helium for Semiconductors and Beyond 2025-2035: Market, Trends, and Forecasts” report will become increasingly essential.

Materials key to hydrogen and helium production

From the ion exchange membranes in electrolyzers for green hydrogen generation to the gas separation membranes used in helium and hydrogen production, the applications explored in this article represent significant opportunities for chemicals and materials companies. Materials for green hydrogen are needed for components such as catalysts, electrodes, porous transport layers, gas diffusion layers, bipolar plates, and gaskets. Innovations include new catalysts with less iridium content to cut costs. For gas separation membranes, the development of new palladium-alloy metallic membranes could unlock ultra-pure H2 separation.